Q2 Smart Lockers: Transforming Dry Cleaning in the Digital Age

Developing a mobile application is a challenge by itself. To create it from scratch, you need to roll up your sleeves together with a highly skilled software house, that will transform your business idea into a digital product. But what if your project requires connecting applications software with some hardware devices? Let’s take a deep dive into the Q2 Smart Lockers case study.

Table of content

Table of Contents

Developing a mobile application is a challenge by itself. To create it from scratch, you need to roll up your sleeves together with a highly skilled software house, that will transform your business idea into a digital product. But what if your project requires connecting applications software with some hardware devices? Let’s take a deep dive into the Q2 Smart Lockers case study.

It will be a strongly retrospective story. A story that happened back in the days when a startup landscape, technology, and application development was slightly different than it is today.

Q2 Smart Lockers Ltd., a startup based in London, teamed up with GMI Software House between 2014-2015 to deliver an ambitious project that merged the newest technology with somewhat traditional services.

The idea – get your clothes cleaned on the move

A while ago, I was chatting with a friend who moved to London from Bristol. I asked him how did he find living in such a megacity. “Mate, it’s hectic, I feel like I was running all the time.”

The pace of life is crazy in today’s world, but it can accelerate even more if your center of the universe is London. Having those dynamics in mind, many startups have come up with solutions designed to help people save their time and hassle. The same idea was behind Q2 Smart Lockers.

The purpose of their product was to let utterly busy professionals dry-clean their clothing while they’re on the move. Instead of going after a brick-and-mortar dry-cleaning and laundry premise, you would only have to drop your clothes in one of the smart lockers scattered all over the city.

Imagine a network of intelligent lockers located near gas stations, subway stations, shopping malls; you name it!

Now, picture a situation – an important meeting in your office the very next day, and your favorite jacket or a dress needs to be cleaned. And you’re going around the clock with plenty of other obligations.

So, all you need to do is to stop by the nearest gas or a subway station and to leave your outfit in a locker and order dry-cleaning service via your mobile app. A carrier collects it from a locker, gets it to the Q2 laundry, they provide a service, and a carrier takes it back to your locker. And all that is happening within a few hours!

Connecting this kind of dry-cleaning service with electronic locker systems by a mobile application – that was Q2’s business goal. After it spreads in London, they were planning to export this solution to other countries, such as Luxemburg.

The timeline

So, we know the goal. Now, it’s time to discover how the story went for Q2. To create an architecture of a smart locker system operated with an app, they needed a proficient outsider – a software development company that is ready to develop a solution that required skills and knowledge on both of levels – hardware and software.

How did they find GMI Software House? Our other customer recommended us to the Q2’s founder – Arek Kozikowski.

What happened next was getting together with their Project Manager to be clear about the scope of the project and their budget.

Collaboration with partners

Before we took off, the Project Manager from Q2 needed to find a subcontractor that will be responsible for the production of smart locker systems and developing software for the operating system built in a locker.

After he managed to find a vendor from China, he passed it on to GMI. We had to work out communication methods with this partner and between their system and our software.

Starting to work on a product

This is where the beauty begun. The project was complicated, so we needed to be clear on setting stages, building a roadmap:

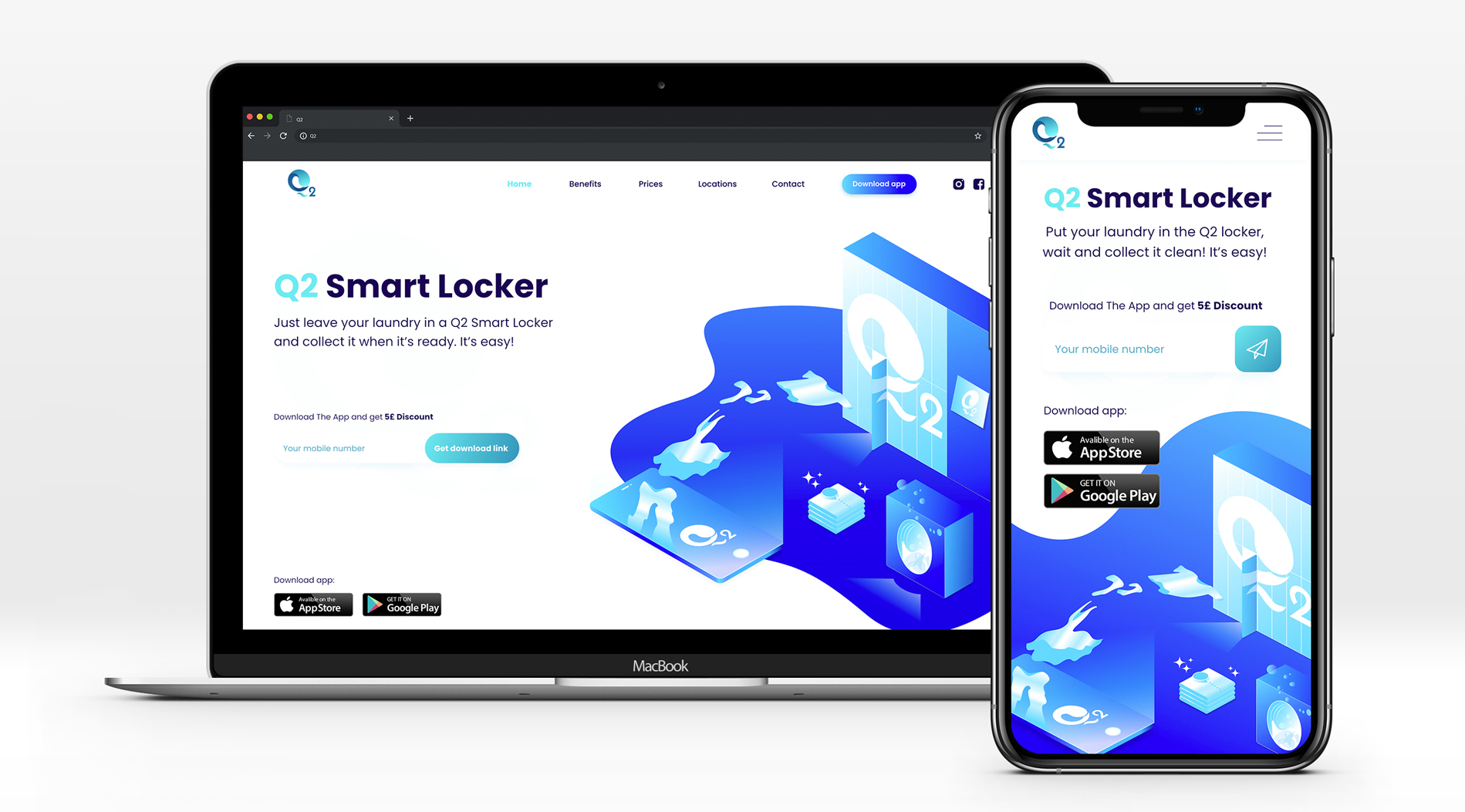

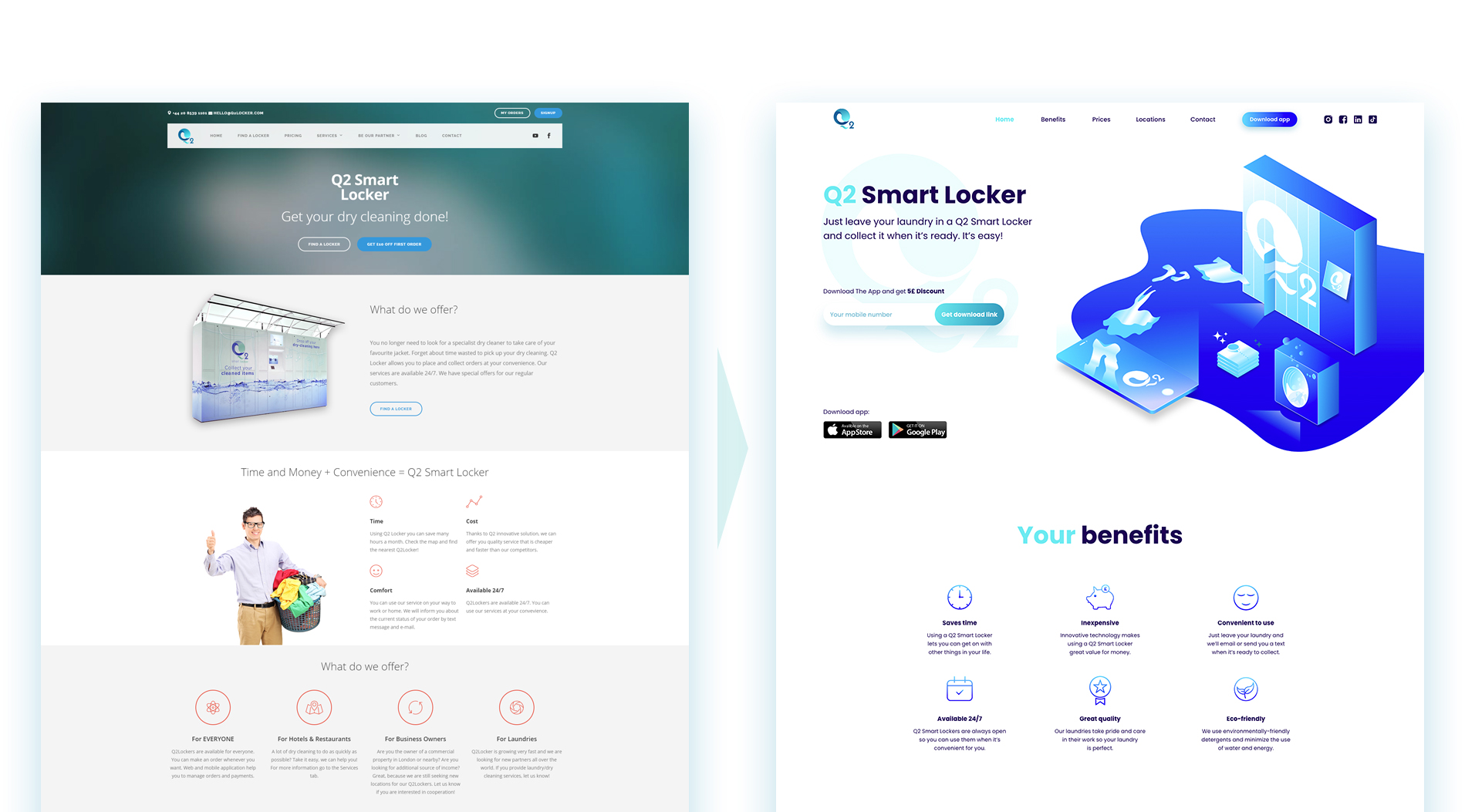

Designing visuals for the entire software

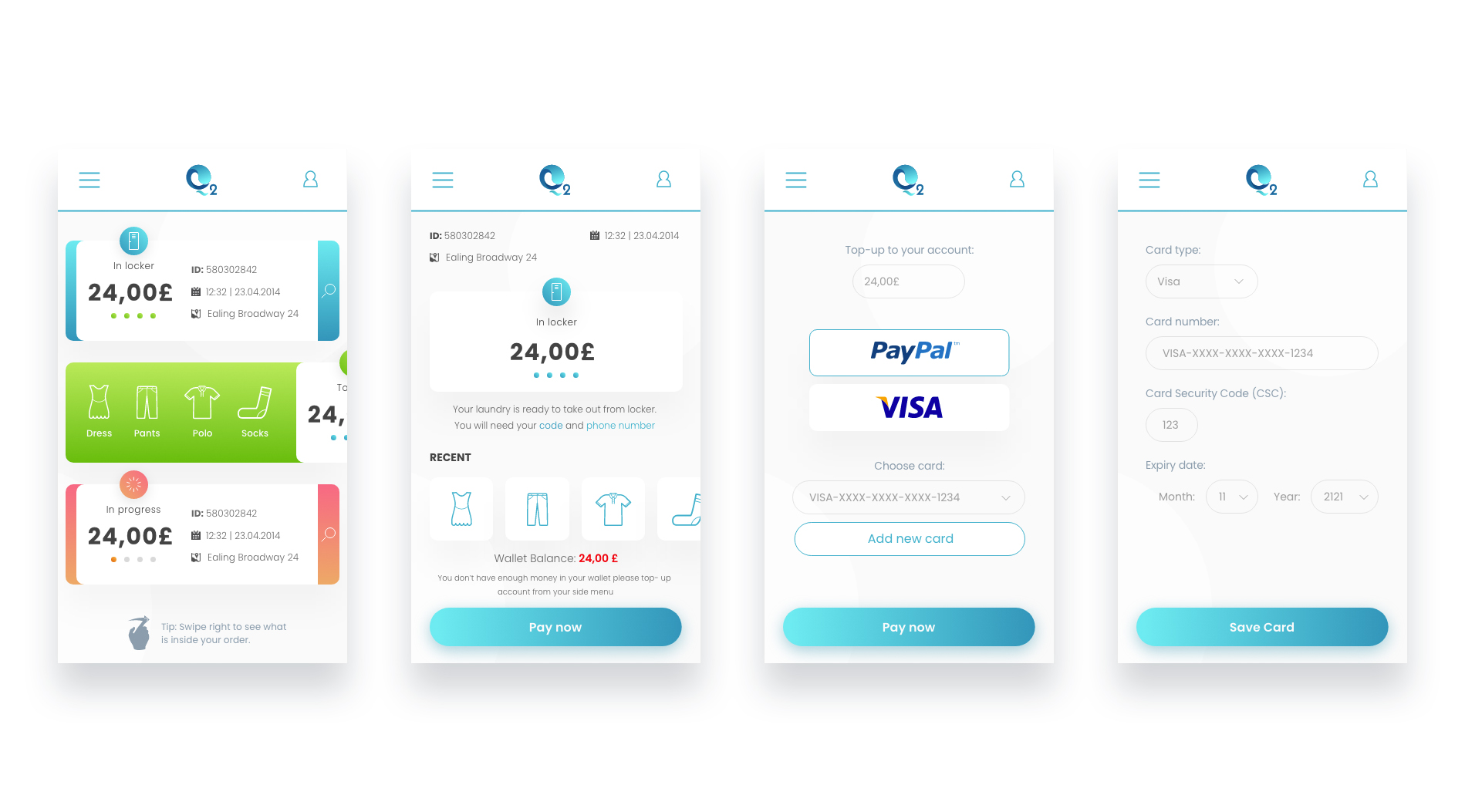

All we received from our new customer was their logo, so we knew that there’s a design process ahead to forge a visual identity for the entire application. This is where our product design workshop approach came in handy. During a set of workshops with our customer, we were able to deliver a few exciting graphics concepts for the entire app interface.

We recall it as a very creative process, packed with inspirational ideas. We had to bear in mind that we were working it out for London, a city famous for its innovative approach towards graphic design.

Developing an app for end-users – processing orders, payments, and notifications

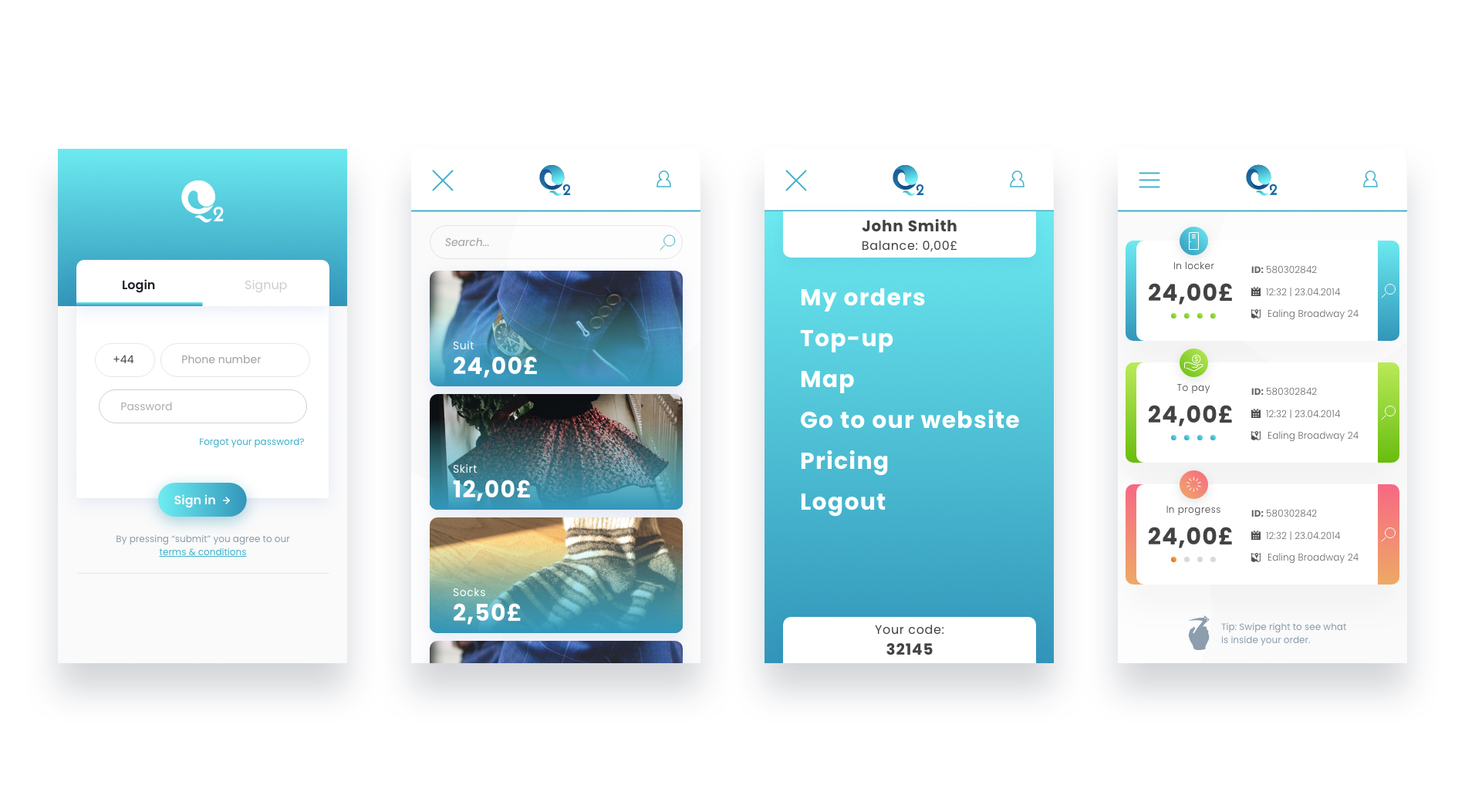

From wording out a concept for an application, through creating first mock-ups, up to building a final product – as agile die-hard believers, there was no other way than to conduct the whole process iteratively.

Working closely with Q2 during brainstorming sessions and workshops, made it clear for us that our shared goal was to reach end-users with an intuitive product. An app to be so user-friendly that users would not hesitate to download and use it. Taking the project to the MVP stage would also empower us to convert users’ feedback to the knowledge we could use in upcoming iterations.

Developing an app for internal users – laundry’s employees

But that’s not all. Creating this locker system wasn’t only about serving an end-user. It required developing a separate application dedicated to the management processes. Q2 Smart Lockers owned a laundry premises, and a far-reaching goal was to create a network of laundry and dry-cleaning places to make the service work faster and more efficiently.

To make the entire service up and running, laundry’s employees needed an easy tool to manage orders placed with the end-user app. The vision was to handle dry-cleaning service at a mass scale, so the staff needed to be prepared for it.

The trick was to deliver that kind of tool that will enable the staff to take care of incoming orders in real-time and at the same time – not to interrupt their other work.

Therefore, we have tested various hardware devices to finally come up with a set of 15-inch touchscreens equipped with barcode scanners. In the meantime, we handed over the first version of the application to the laundry’s employees. They were supposed to try it out and get back to us with precious feedback.

Developing a back-office app for Q2 administration

That was an MVP approach at its finest. We knew that until the dry-cleaning lockers solutions won’t conquer the local market and generate a stream of active users, there’s no need to build an oversized reporting system.

All we needed to develop at this stage was a business management application to control the smart locker network, as well as the pricing and the payments, but with a minimum set of features.

Thanks to focusing only on the essential functionalities (business-wise), we were able to build a back-office app shortly, and without ruining the budget.

Developing a mobile app for end-users

To win back some of our time, we used hybrid technology to deal with the app for Android and iOS simultaneously.

There were a couple of mantras we have prayed and followed during the entire development process:

- Transparency. We focused on delivering a mobile app with a crystal-clear display of placed orders.

- Simplicity. One of our goals was to provide this kind of payment process that would let each user know the order’s status in a friendly and fast way.

- Sense of control. If a customer feels that nothing gets out of hand with placing and executing the orders, then we can say that everything works the way it should.

The alpha tests stage

As I mentioned before, to launch smart lockers in the United Kingdom, we figured out that the best option is to import the hardware from China.

After a few weeks, a test locker got shipped to our office in Poland. We carried it on our backs, and there it was – all waiting to be explored. It was super exciting to play around with this new toy, and most importantly – to see things at its infancy.

But playing around with the test locker and its built-in software led to the first obstacle. It turned out that there is no option to architecture the entire process relying on Chinese software.

What was the solution?

Time to be bold – building our application for the locker

OK, so we ran into an issue and a conclusion that our primary assumption was wrong. The Chinese software didn’t match the Q2 business needs. For instance, the application that got to us from Asia was managing totally different processes than the app we have developed earlier on.

What we’ve got was a ready-made technology wrapped up for the sake of the Chinese market but covered with the Q2 logo and visual identity we have designed. The process ordering and executing orders was copied/pasted from the previous solution, and it didn’t tune it to what we have worked out.

How about some reverse engineering?

What were our options here? All we were left to do was to unleash our reverse engineering thinking! We had to figure out (backwords) how the Chinese tech solution communicates with all the hardware elements in the locker, such as locks or sensors.

Let’s take locks as an example. When we stripped the locker to get to the lock itself, it turned out that it’s a no-name product, and it’s impossible to find any technical details about the drivers and controllers.

Therefore, reverse engineering was the only way to go. We had to do a surgical operation on their old app to get our hands on the lock control module. As soon as we knew how it works, we developed a better version of the module.

Let’s build a new mobile app

Since we managed to get hardware under control, our next step was to develop an application that will meet the Q2 Smart Lockers’ business needs.

As we moved along, we could implement the new interface design, and without exceeding the costs.

London calling – beta tests are coming

When we finished configuring hardware and developing software, we got out of our software house laboratory in Cracow. First five lockers were all ready for a trip to London.

Setting up the lockers

While Chinese lockers found their way to Great Britain across the seas, two of us got the plane to configure the hardware in the British capital. When we arrived, lockers were already plugged in. All we needed to do was to turn them on and connect them to the entire Smart Lockers’ platform.

It may sound like something trivial, but it wasn’t always easy. There were places with unstable network coverage, and it was crucial to ensure a seamless connection. Nevertheless, we managed to keep five lockers up and running.

Training sessions for laundry employees

Next, we paid some visits to laundries/dry-cleaning stores that joined the project and implemented the Q2 platform. Our mission was to walk their employees through the Q2 order processing panel.

As we were showing them each corner of the system, we also were explaining different use-case scenarios, such as dealing with discounts, damaged clothing, returns, and cancellations.

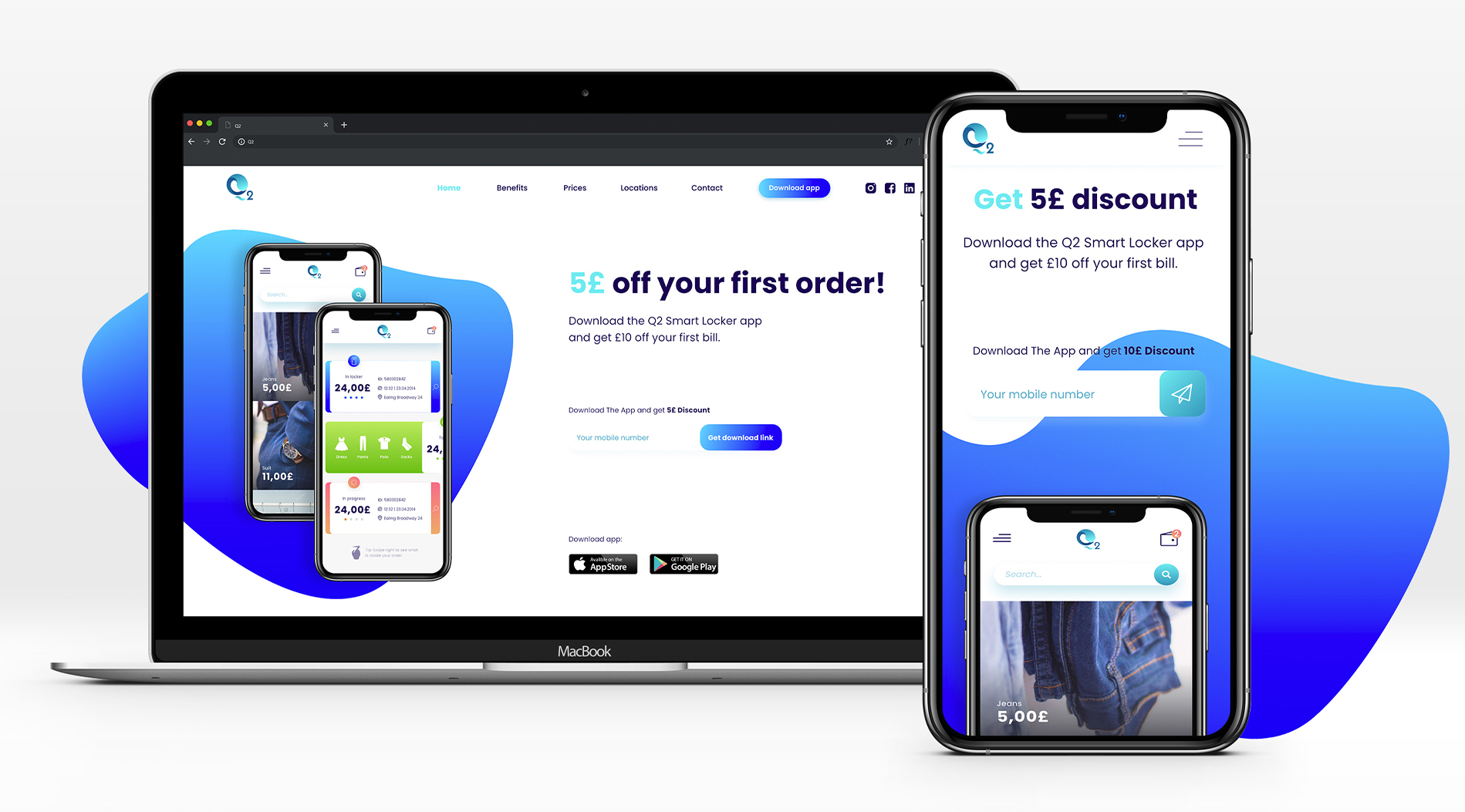

Running first offline and online marketing campaigns

At this point, we proved once again that GMI was always way much more than just a software development company. We’ve got deeply involved in the Q2 business project and taken some initial marketing efforts on our shoulders.

Before we landed in London, Q2 was already after some traditional, offline marketing activities, like handing over leaflets or branded balloons. However, it was not enough. As a software product, Q2 Smart Lockers required a digital marketing approach.

We planned and deployed a PPC campaign that not only generated traffic but also triggered first registrations on the platform. Users who created their accounts received a 10 GBP voucher for the first order.

It led to…

First paying customers

It was super exciting to see how it’s starting to work. Investing in a paid campaign on social media began to pay off – first, customers placed their orders and showed up in front of lockers to leave their clothes for dry-cleaning.

Want to build a similar product? Don’t hesitate to contact us!

[contact-form-7 id=”134″ title=”Contact form 1″]

What’s next?

Like in every business, the project launch is just a beginning. To keep on thriving, it requires subsequent investments and iterations. After releasing smart lockers, together with Q2, we entered another stage.

First, to know what’s working and what’s not, we needed to collect some invaluable feedback – internal (from laundries’ employees) and external (from customers).

Equipped with that knowledge, we were all set to kick off an iteration process. Our aim was to develop a second version of the lockers’ application. To do that, we had to:

- Roll up our sleeves and do some serious hardware work. The production of new lockers was about to take place in Rzeszów, Poland;

- Inject necessary changes in the application to enable contactless payments and to work with brand-new 17-inch screens. As a result, the interface got enriched by a few new views.

- Implement smart lockers’ solution to Luxemburg’s market with the help of building a franchise partnership.

Q2 Smart Lockers – project’s challenges and solutions

This case study is unusual. Why does it stand out from the crowd? Mostly because our role as a software development house wasn’t limited to writing code and ability to convert programming languages into a good-looking app.

We can firmly say that we played a strategic role in the entire project – from transforming an idea into a prototype, through designing a brand identity and a visual interface, through configuring lockers, up to employee training and running a digital marketing campaign!

It was a complex project that involved flexibility and facing some significant challenges:

Challenge no 1

First off, the project wasn’t just about coding the app but building a physical, tangible product, fueled by technology.

We had to go on a hunt, looking for an outsider, who has already produced lockers we needed. From the start, everything relied on hardware built in China.

The challenge here boiled down to merging two styles of communication, and two approaches towards pretty much the same product.

The Solution

Together with the Chinese side, we established particular hours to run online communication that would match two different time zones.

We have assigned a software architect on our side to cooperate with the Chinese team closely. To idea was to create a way their lockers’ software and our applications to “talk” to each other.

It went well! After a couple of iterations, both systems communicated seamlessly by exchanging all the critical data.

Challenge no 2

When it comes to laundry and dry-cleaning services, the British market, and London in particular, is quite specific. The competition is enormous. There are many laundries scattered all over the city that you could close your eyes, throw a rock, and hit one!

Londoners have been using those services for years, and that’s bad and good news at the same time. Bad because if you start a business in this niche, you will be like a small fish in a red (bloody) ocean. Good, on the other hand, because there’s a strong demand for cleaning clothes this way.

The challenge was to get noticed in this noisy market and to raise awareness of a new solution, where everybody got used to the old-school one.

The Solution

Although the initial idea was to expand the reach of Q2 Smart Lockers’ services worldwide, we knew that we need to settle it on a local market first.

Following the MVP philosophy, we aimed at releasing a pilot version of a system, to quickly start interacting with people. The first wave of customers gave us all the feedback we have wished for. After a while, we knew what product features were essential for them, and what functionalities need to land in a product backlog, waiting for upcoming iterations.

Challenge no 3

It’s trivial, but even the most innovative technology projects don’t come to life in a vacuum. There’s a high chance that, even if you think your business idea is remarkable, someone on another side of the planet has come up with something similar.

By the time we have been developing smart lockers, the competitors raised their heads, mainly on the Polish market. Time was chasing us.

The Solution

Again, focusing on the MVP was the way of the samurai. We needed to deliver the first version of software fast, but with crucial features for end-users, including placing and processing orders and web and mobile payments.

The final result

Together with Q2 Smart Lockers Ltd, we managed to deploy five lockers in London and to make hundreds of pioneer customers gravitate to the product.

Moreover, the feedback we have gathered and the experience that we have gained during the implementation process gave us all the ingredients needed to cook up the product backlog for future iterations.

Last, the word spread, and a company from Luxemburg was vividly interested in partnering up to launch smart lockers in their country.

Are you ready to write your story with GMI?

The most striking takeaway from this case study comes down to this sentence: GMI Software House is not a body-leasing, code-writing company. We have whatever it takes to become an actual business, strategic partner to create a product, even when it involves getting our hands dirty by building hardware and connecting the wires.

The Q2 story shows that we can take good care of:

- designing interface visuals and brand identity;

- connecting custom-made hardware with high-quality software;

- training company’s employees on how to use a platform;

- running marketing campaigns and coming up with possible business partnerships.

So, are you planning to create a game-changing product that will revolutionize your niche? Then you came to the right place! Reach out to us for a project estimation!